|

Grinding :

When two materials of different hardness rub or abrade against each other, its a grinding phenomenon. Where in one surface looses certain amount of its top layer. Grinding further evolved majorly into cylindrical, surface and center-less to metal finishing operations at the highest accuracies in profile. Abrasive materials : Researchers then explored and invented various material of varying hardness and application. Natural Abrasives : Emery is the most natural abrasive material found in nature. It largely consists of corundum (aluminium oxide), mixed with other minerals such as the iron-bearing spinels, hercynite, and magnetite, and also rutile (titania). Turkey and Greece have the world's highest deposits. |

Synthetic Abrasives :

Later Aluminium oxide, Silicon carbide, Zirconium, Combinations of Aluminium oxide treated with various other chemicals vapors.

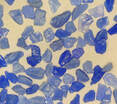

Each of these abrasive material have its unique way of abrading and that decides its applicability. Some abrasive materials wear out , some crack, some stick out due to their hardness. The more advanced of these synthetic materials is chemically formulated ceramic abrasives where they tend to be long in shape and develop micro-crack when applied opening new sharp edges as their are applied.

Later Aluminium oxide, Silicon carbide, Zirconium, Combinations of Aluminium oxide treated with various other chemicals vapors.

Each of these abrasive material have its unique way of abrading and that decides its applicability. Some abrasive materials wear out , some crack, some stick out due to their hardness. The more advanced of these synthetic materials is chemically formulated ceramic abrasives where they tend to be long in shape and develop micro-crack when applied opening new sharp edges as their are applied.

Abrasive Article or Products :

All these above abrasive materials are bonded together with binding agents into a variety of shapes and sizes. The most common of them being the grinding wheels in round circular shape.

Bonded and Coated Abrasives :

Binding Agents : Phenol Resin, Shellac, Magnesite, Electroplated, Vitrified bonds, certain organic bonds.

Resin : finds its most application in Cutoff wheels.

Electroplated : Where a very thing layer of diamond abrasive is required. Mostly with diamond wheels.

Vitrified bonds : serve a versatile application where form or profile grinding is required. Vitrified bonds also allow certain amount of induced porosity for free flow of coolants and free cutting with open edges.

Organic rubber bonds : Find its applications in regulating / cutoff and polishing application.

All these above abrasive materials are bonded together with binding agents into a variety of shapes and sizes. The most common of them being the grinding wheels in round circular shape.

Bonded and Coated Abrasives :

Binding Agents : Phenol Resin, Shellac, Magnesite, Electroplated, Vitrified bonds, certain organic bonds.

Resin : finds its most application in Cutoff wheels.

Electroplated : Where a very thing layer of diamond abrasive is required. Mostly with diamond wheels.

Vitrified bonds : serve a versatile application where form or profile grinding is required. Vitrified bonds also allow certain amount of induced porosity for free flow of coolants and free cutting with open edges.

Organic rubber bonds : Find its applications in regulating / cutoff and polishing application.